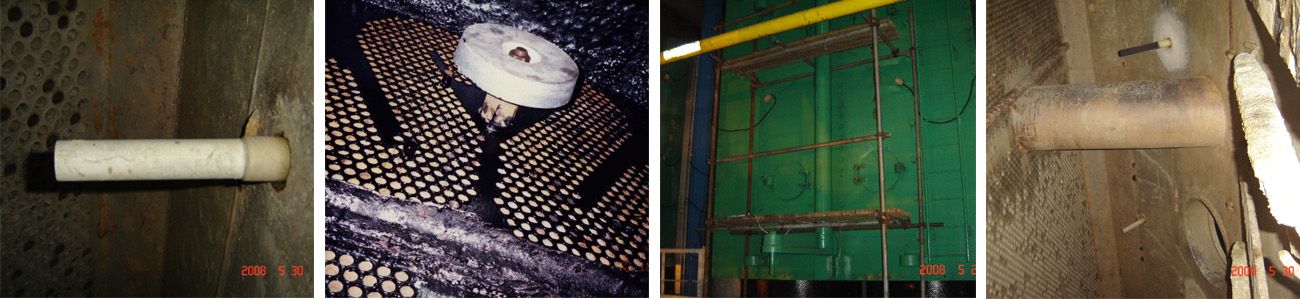

(1) Galvanic corrosion generated by the contact of different metal materials;

(2) Dezinc corrosion of copper alloy;

(3) Corrosion generated by the residual stress due to the heat exchange tube end expanding;

(4) Inlet corrosion caused by the turbulence of the tube end;

(5) Deposit corrosion generated by the impurity;

(6) Pitting corrosion caused by the marine pollution.

Corrosion of Expanding Point of Condenser Tube and Tube Plate